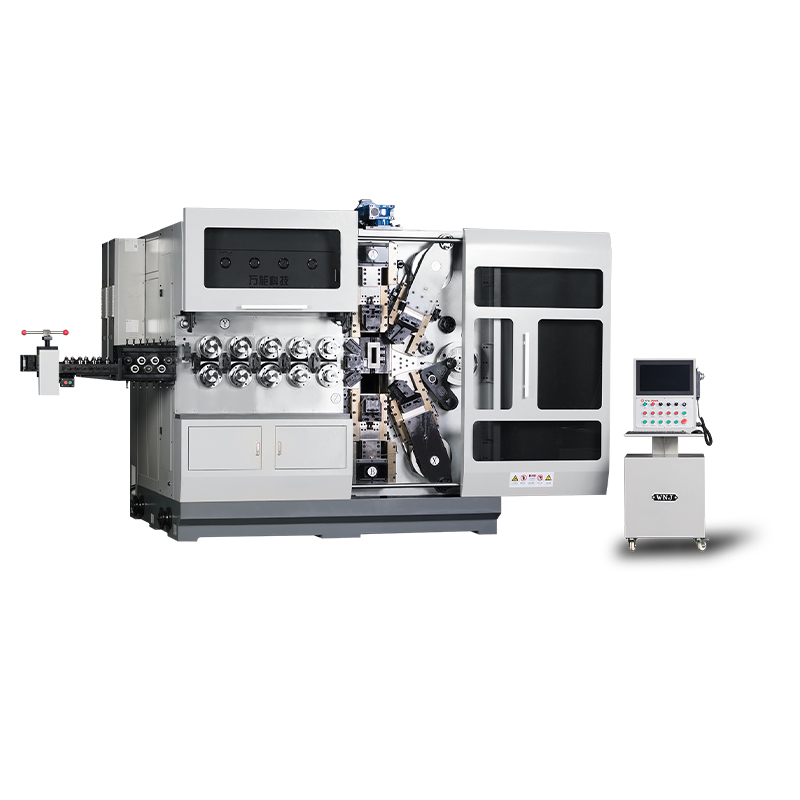

O Máquina dobradeira de fio de mola CNC de 4 eixos adota mecanismos de transmissão precisos, como fusos de esferas, guias lineares, etc. Esses componentes possuem características de baixo atrito, alta precisão e alta rigidez, o que pode garantir a precisão e estabilidade da máquina em movimentos de alta velocidade. O sistema de guia adota dispositivos de guia de alta precisão, como rolamentos e guias de precisão, para reduzir a folga e o atrito entre as peças móveis, melhorando ainda mais a precisão da máquina.

O machine is equipped with high-precision sensors, such as displacement sensors, angle sensors, etc., which can monitor the movement state and position information of the machine in real time. The feedback system collects sensor data in real time, compares and adjusts it with the preset processing parameters, and ensures the accuracy and consistency of the machine during the processing.

O control system adopts advanced control algorithms, such as PID control, fuzzy control, etc., which can accurately control and adjust according to real-time feedback data to ensure the stability and accuracy of the machine during the processing. The control system also has powerful data processing capabilities, which can handle complex processing tasks and complex motion trajectories to achieve high-precision processing.

O machine adopts a sturdy and durable structural design, such as cast iron bed, high-strength steel plate, etc., which can resist external shock and vibration, ensuring the stability and precision of the machine under long-term operation. The structural design also takes into account the influence of thermal deformation, and adopts reasonable heat dissipation structure and thermal compensation measures to reduce the deformation of the machine caused by temperature changes.

O servo drive system adopts high-performance servo motors and drivers, which are characterized by high precision, high response and high stability. The servo drive system can monitor the operating status and load of the motor in real time, and adjust and optimize as needed to ensure the stability and precision of the machine during processing.

O machine is equipped with complete maintenance and maintenance measures, such as regular lubrication, cleaning and inspection, to ensure the stability and precision of the machine under long-term operation. Users can also perform regular maintenance and maintenance according to the use and needs of the machine to extend the service life of the machine and improve its stability.

TK-13200, TK-7230 TK-13200、 TK-7230 12 EIXOS CNC MÁQUINA DE ENROLAMENTO DE MOLA ...

See Details

TK-13200, TK-7230 TK-13200、 TK-7230 12 EIXOS CNC MÁQUINA DE ENROLAMENTO DE MOLA ...

See Details

TK12120 TK-12120 12 EIXOS CNC MÁQUINA DE ENROLAMENTO DE MOLA ...

See Details

TK-6160 MÁQUINA DE LAMINAÇÃO DE MOLA CNC TK-6160 ...

See Details

TK-6120 MÁQUINA DE LAMINAÇÃO DE MOLA CNC TK-6120 ...

See Details

TK-5200 TK-5200 5 EIXOS CNC MÁQUINA DE ENROLAMENTO DE MOLA ...

See Details

TK-5160 TK-5160 5 EIXOS CNC MÁQUINA DE ENROLAMENTO DE MOLA ...

See Details

TK-5120 TK-5120 5 EIXOS CNC MÁQUINA DE ENROLAMENTO DE MOLA ...

See Details